Recommended articles:

-

-

Global Energy Interconnection

Volume 8, Issue 5, Oct 2025, Pages 719-731

Mechanical performance of key components in floating photovoltaic systems: technological advances and application prospects

Abstract

Abstract Floating photovoltaic (FPV) technology is emerging as a highly promising approach to accelerate decarbonization of the global economy, due to its higher power generation efficiency and lower land occupation.With the rapid development of FPV technology, the mechanical performance degradation of key components caused by the harsh marine environment has become a pressing issue, as it significantly contributes to failure behavior observed in FPV systems.A comprehensive compilation of the mechanical performance of key components in FPV systems is also currently unavailable.Here, the mechanical behavior of each structural component in FPV systems under harsh marine environments is systematically reviewed.It further emphasizes the synergistic effects of mechanical performance degradation among different components on the overall system.The drop-off rate (v) of normalized elongation at break(EAB) of polymer under the synergistic effect of various environmental factors increases from 7.5 10 4 h 1 to 21.8 10 4 h 1 compared with the single environmental stress.Moreover,the development of novel materials and innovative mechanical structures applied in FPV systems to enhance mechanical performance is discussed.The novel flexible PV modules applied in FPV systems minimize the loads acting on the mooring lines by 80% and increase power generation by 5%.Notably, this paper provides a theoretical foundation for developing standards of FPV systems, especially the establishment of standards related to the synergistic effects of the mechanical performance degradation of different key components on FPV systems.

0 Introduction

Developing renewable energy is pivotal for addressing global energy crises and environmental issues, and achieving cleaner and sustainable development[1,2].Solar energy has been actively developed in recent years due to its pollution-free, rich and wid ely distributed.Harnessing available solar energy through photovoltaic (PV) systems can be among themost efficient methods to replace traditional power generation systems [3,4].PV power generation has grown rapidly and is expected to account for 70% of global electricity generation by 2050 [5].The utilization of floating photovoltaic (FPV) technology offers a viable solution to the challenges posed by space limitations in the field of land-based photovoltaic (LPV) development [6,7].In addition to conserving land, FPV systems have higher productivity and efficiency than LPV systems, due to the cooling effect of water on the panels [8].The evaporative cooling effect reduces the ambient temperature near the water surface, providing a cooler environment for the FPV systems.Consequently, the rise in temperature difference relative to the module temperature results in the release of thermal stress, leading to a reduction in the module temperature [9].Moreover, the water helps to clean the panels, reducing dust build-up and further improving power generation efficiency [10].Overall, FPV systems can increase PV module efficiency by 12-13% or more [11,12].

Despite the many advantages of FPV systems,they face challenges in maintaining structural safety and mechanical stability under the effect of marin e conditions during their service life [13,14].The key components of a FPV system consist of PV modules, floating structures, mooring systems and connection components.The mooring systems,as the foundational structure, must withstand the significant mechanical loads from waves and wind, and maintain excellent mechanical performance.Dynamic loads from waves can cause floats to overturn or generate increased movem ent during waves, resulting in stress on the mounting structure.Continuous strong wind and intense vibration can make floating structures more susceptible to cracking or fracturing,resulting in the decrease of mechanical properties [15].PV modules are subjected to continuous strong wind and wave forces, which can result in the formation of microcracks, ultimately reduce fatigue strength [13].The stability and impact resistance of PV modules are essential to ensure power generation efficiency and long-term stable operation, while the connection components need to resist corrosion and mechanical fatigue.The efficiency and lifetime of the FPV system is directly affected by the mechanical performance and durability of each key component.Accordingly,it is vital to thoroughly assess the strength,toughness,fatigue resistance,and ability of these components to withstand extreme loads in harsh marine environments,ensuring the safety and stability of FPV systems.

The aim of this review paper is to systematically analyze the mechanical behavior of each structural component in FPV systems under harsh marine environments.Additionally, the development of novel materials and innovative mechani cal structures applied in FPV systems to enhance mechanical performance is discussed.Unlike previous studies that primarily focus on individual components or specific environmental factors,this paper comprehensively investigates the mechanical performance of key components in FPV systems under various environmental factors.It further emphasizes the synergistic effects of mechanical performance degradation among different components on the overall system, providing a theoretical foundation for developing standards of FPV systems.Notably, this review offers recommendations for the establishment of standards, especially regarding the formulation of standards for the synergistic effects of different environmental factors on mechanical perfor mance of key components.Finally, this paper provides suggestions for the future development of FPV systems and prospects for the establishment of the new energy nexus.

1 The structure and advantages of FPV technology

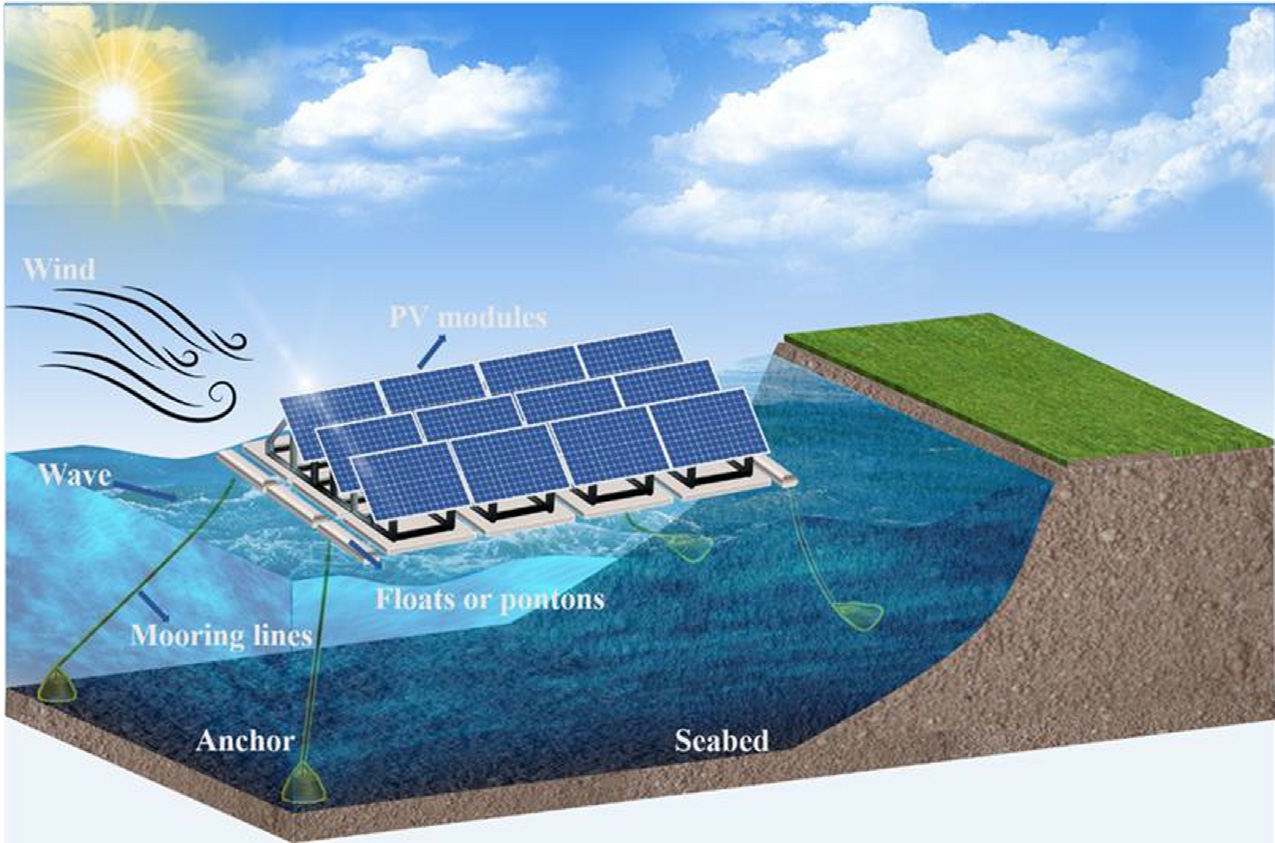

The FPV systems are composed of several key components that work together to harness solar energy efficiently in marine environments: PV modules, floating struc tures,mooring systems [1,16,17].Fig.1 shows the key components in FPV system.The design of these components must take into account the specific characteristics of the marine environment, such as wave, wind and salt corrosion.

PV modules, the core components of FPV systems, convert solar energy into electricity.Typically constructed from monocrystalline or polycrystalline silicon,these modules are equipped with waterproof and anti-salt fog features to ensure reliable performance in harsh marine environments[1].The floating structure of the FPV system consists of buoyancy modules or platforms that ensure system stability.These platforms are typically anchored to the seabed to prevent drifting caused by waves and currents.The anchor is a crucial part of the mooring system, which consists of mooring lines, fairleads, and tensioners [18].The mooring system is crucial for securing the floating platforms and ensuring their stability, protect ing them from the forces of wind, waves, and currents [19].

FPV technology is emerging as a highly promising approach to accelerate decarbonization of the global economy, due to its higher power generation efficiency a nd lower land occupation [20].By utilizing water surfaces for installation, FPV systems avoid the substantial expenses associated with land acquisition and preparation,making them an economically vi able option in these areas[21].In arid regions, FPV system also contribute to water conservation by reducing evaporation, which supports local water resource management [22-24].The ability to produce energy while conserving water positions FPV as a highly suitable option for nations facing challenges with both energy and water resources [25].

Fig.1.The structure of FPV system.

Moreover, the FPV system utilizes the cooling effect of water, which reduces thermal drift compared to LPV,thereby increasing efficiency [26,27].Additionally, FPV technology contributes to greenhouse gas emission reductions by offsetting non-renewable energy sources, aligning with global renewable energy goals.For example, installing FPV systems on just 10% of suitable water surfaces could supply around 31%of Spain’s electricity needs while reducing non-renewable energy production by 81% [28].FPV systems also help improve wate r quality by inhibiting algae growth through shading,which reduces maintenance costs and enhances the ecological balance of the water body [29].

These structural and technological advantages demonstrate that FPV systems not only provide a sustainable and efficient energy solution but also offer significant environmental and economic benefits.By integrating renewable energy generation with water conservation and environmental protection, FPV is set to become a crucial solution for global energy.

2 The threat caused by the decrease in mechanical performance of key components

The key components in FPV systems are subjected to dynamic loads from the mari ne environment, which can lead to a decrease in fatigue strength [30-32].When components are subjected to excessive stress, it can cause fracture failure.

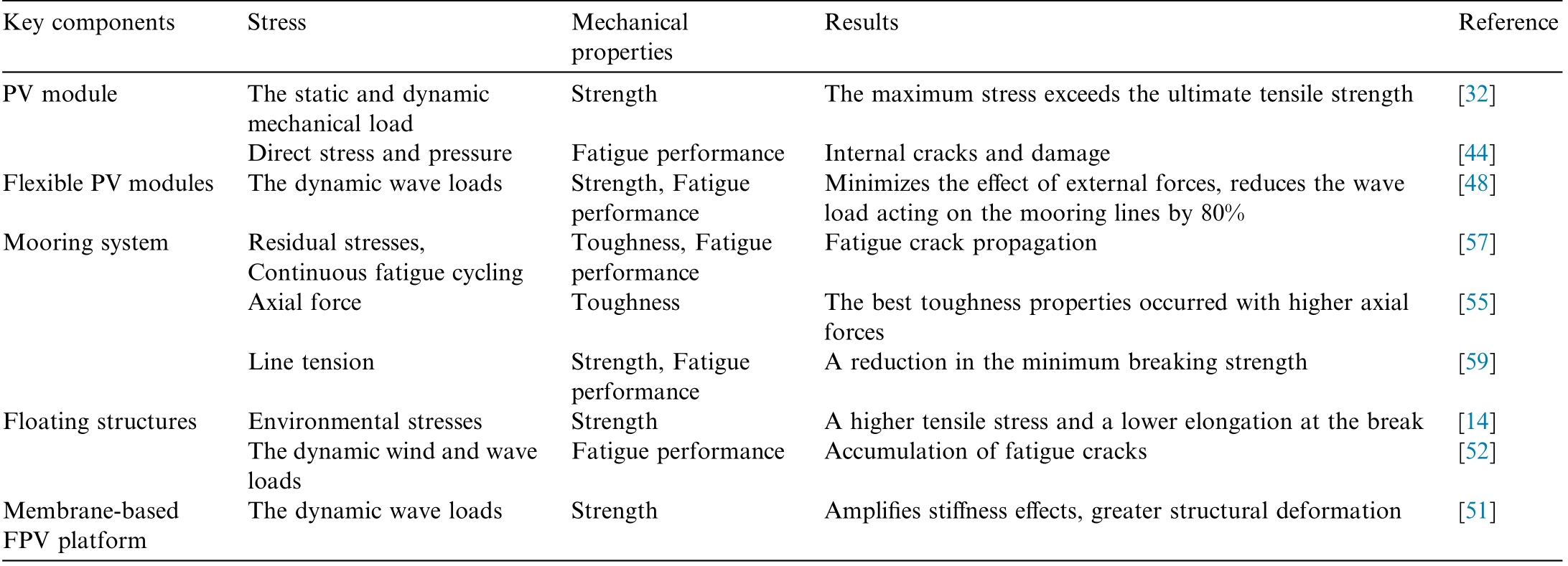

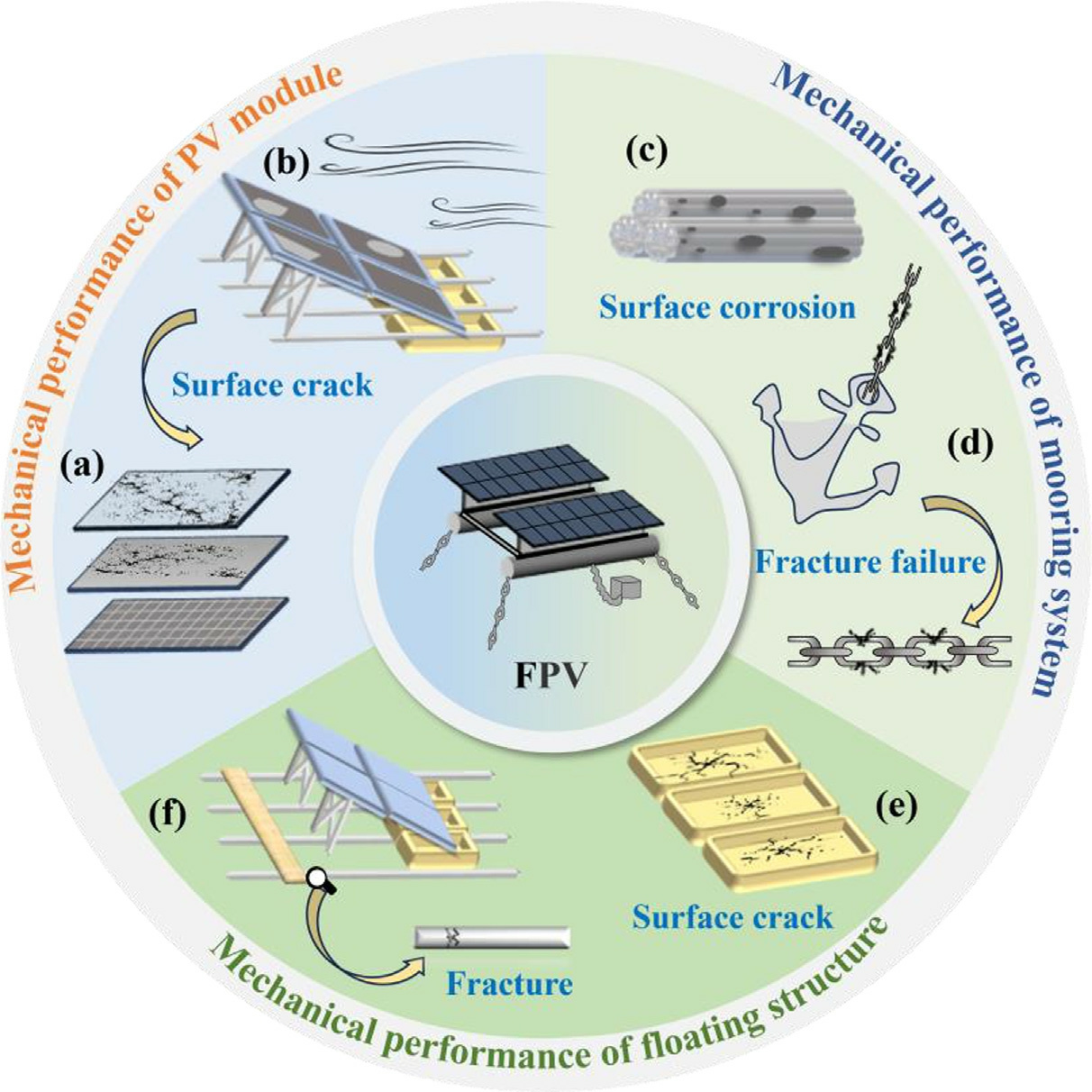

Table 1 shows the summary of some studies on mechanical properties of key components in FPV systems.Understanding these mechani cal stresses is essential to optimize their mechanical design to achieve long-term reliability,and prevent system failures [30,32-34].Fig.2 shows the threat caused by the decrease in mechanical performance of key components in FPV systems.Long-term exposure of components to cycli cal stresses caused by wind and waves can result in the formation of microcracks on the surface of the PV modules, ultimately leading to mechanical degradation.The wind and waves present in the marine environment have been shown to exert a significant influence on the mechanical properties of floating structure.The load caused by wind can lead to stress concentration and fatigue failure of floating structures.The periodic dynamic loads and impact forces caused by wave action have been shown to exacerbate the fatigue damage of the structure and trigger crack propagation.Corrosion pits on surface of mooring chains induced by fatigue and corrosion behavior cause significant stress concentration under axial tension, accelerating the transition from elastic-plastic deformation to brittle fracture.In order to mitigate the impact of mechanical loads on key components, flexible FPV systems have been developed.In comparison with conventional rigid systems, flexible FPV systems have the capacity to deform under dynamic wave loads and demonstrate resistance to mechanical stresses and fatigue damage.

2.1 Mechanical performance of PV module

In offshore environments, the mechanical performance of the PV modules should be concerned especially [35-37].Environmental factors, such as wind speeds ranging from 5 to 15 m/s and wave heights reaching up to 4 m,continuously impose loads on the modules,generating cyclic stresses that contribute to fatigue and mechanical degradation, including the initiation of microcracks on the module surfaces [38].Over time, this cumulative stress may exacerbate existing defects, reduces the structural integrity and durability of the PV modules [39].

Current research focuses on assessing the mechanical responses of PV modules under various environmental conditions, particularly the impact of wind loads.Numerical simulations and experiments have revealed key factors,such as wi nd speed, direction, and turbulence intensity,that influence the structural performance of PV modules.For instance, several studies have analyzed PV modules under different turbulence intensities and wind speeds,and found that the mechanical loads on the modules varied with different wind directions [40,41].Nikoleta et a l.[33] evaluated and compared the mechanical loads experienced by the module from strong wind on a FPV platform,as well as their effects on the stress induced within the module.Further studies highlighted that high wind speeds lead to greater deflection and increased risks of structural fatigue, particularly for floating supports [42,43].Wind tunnel tests [44] showed that PV modules mounted on cables are susceptible to strong torsional vibrations, which exceed vertical oscillations as wi nd speed increases, affecting the mechanical performance of the modules.Lim et al.[45] applied direct stress and pressure to the PV modules to assess the mechanical reliability.The results showed that the applied load caused internal cracks and damage on the PV modules.

Table 1 Summary of some studies on mechanical properties of key components in FPV systems.

Mechanical propertie s Key componentsStressResultsReference PV moduleThe static and dynamic mechanical load Flexible PV modules The dynamic wave loadsMinimizes the effect of external forces, reduces the wave load acting on the mooring lines by 80%StrengthThe maximum stress exceeds the ultimate tensile strength[32]Direct stress and pressureFatigue performanceInternal cracks and damage[44]Strength, Fatigue performanc e Mooring systemResidual stresses,Continuous fatigue cycling[48]Toughness, Fatigue performanc e Fatigue crack propagation[57]The best toughness properties occurred with higher axial forces Axial forceToughness[55]Strength, Fatigue performanc e Line tensionA reduction in the minimum breaking strength[59]Floating structuresEnvironmental stressesStrengthA higher tensile stress and a lower elongation at the break [14]The dynamic wind and wave loads Fatigue performanceAccumulation of fatigue cracks[52]Membrane-based FPV platform The dynamic wave loadsStrengthAmplifies stiffness effects, greater structural deformation[51]

Fig.2.The threat caused by the decrease in mechanical performance of key components.(a) Surface cracks of PV glass, (b) Interfacial delamination in PV modules, (c) Surface corrosion of steel used in anchor, (d) Fracture failure of steel, (e) Surface cracks of floats, and (f) Fracture of floating structure.

Ultraviolet (UV) radiation presents a substantial and non-negligible threat to the lifetime of PV modules [15].Long-term exposure to UV radiation can accelerate the degradation of materials used in PV modules thereby reducing the mechanical properties of modules,eventually affecting power generation efficiency [46].Salt spray poses a significant threat to offshore PV systems, as it erodes the surface coating of PV modules, causing the protective layer to fail and damaging structural components,thereby reducing the mechanical performance of the system and ultimately affecting the safety and economic benefits of the entire PV power plant [47].

The thin film flexible FPV system has the ability to deform under dynamic wave loads, which is expected to minimize the loads on structures.The less weight of PV modules results in reduced weight of the structures and mooring stress.Thin film-based FPV are usually aligned with the water wave direction, and the system tends to have reduced wave attenuation.This minimizes the effect of external forces acting on the system significantly.The minimal wave energy interaction reduces the wave load acting on the mooring lines by 80% [48].The flexibl e design of the PV modules offer reliability to deploy the FPV system in an offshore environment with an average 5% increase in energy yield compared to other offshore power-generating technologies [49].

In summary, the marine environment poses severe challenges to the mechanical performance of PV modules for offshore applications.These challenges include the effects of different factors such as salt spray corrosion, wind and wave loads, and irradiation.Long-term exposure to harsh marine environments can result in the formation of microcracks on the surface of the PV modules, ultimately leading to mechanical degradation.The development of flexible PV modules reduces the weight of the structure and the stress bor ne by mooring, improving the reliability of FPV systems during operation.In the future,it is necessary to pay more attention to the synergistic effects of different marine environmental factors on the mechanical performance of components.

2.2 Mechanical performance of floating structure

A floating structure supports the PV panels, enabling them to float on the water.High-density polyethylene(HDPE) is commonly used for floats because of its excellent tensile strength.However, the repeated bending and torsional stresses can cause the platform to experience fatigue.Over time, these mechanical stresses may lead to deflections, weakening the platform’s overall ability to support the PV modules.The platform can experience failure if the accumulated fatigue exceeds the structural capacity of the platform’s components, potentially leading to collapse or significant damage.Lee et al.[50] investigated the mechanical properties of fiber reinforced polymeric plastic (PFRP) members used in the FPV syst em through mechanical testing.The test data was utilized to establish the allowable stress of PFRP materials with safety factors.Finite element analysis showed that the module structure of the FPV system and the connections between the units could effectively withstand external loads.

Wave-induced forces significantly impact the mechanical performance of FPV platforms.Zhang et al.[51] studied a membrane-based FPV platform subjected to wave frequencies ranging from 0 to 2 rad/s and observed that increasing wave frequency amplifies stiffness effects, resulting in greater structural deformation.Claus’s experiments showed that wave-induced motions significantly affect the platform’s stability[52].Choi et al.[40] analyzed the aerodynamic effects induced by wave motion and observed significant variations in lift and drag coefficients, which were attributed to the amplitude and phase lag of platform motion.These variations directly influence the mechanical performance of the platform.Experimental data from the North Sea further validate these findings, showing that lower wave heights correlate with reduced fatigue strength requirements for FPV systems, thus influencing the mechanical integrity of the platform [53].

The mechanical behavior of floating structures is influenced by both material properties and external loads, such as waves and wind.Numerous studies have been conducted to evaluate the fatigue resistance performance of HDPE and PFRP materials when used in floating structures.Meanwhile, the mechanical stability of the platform under various marine environmental conditions has been verified through finite element analysis and experimental studies.However, further investigation is necessary to comprehensively evaluate the coupled effects of waves and wind on the platform’s long-term performance.Additionally, the mechanisms by which the combined marine environmental factors influence the overall structural durability remain to be fully clarified.

2.3 Mechanical performance of mooring system

The primary purpose of the mooring system is to secure the FPV system and ensure its positional stability.It consists of anchors and chains that connect the floating platform to the seabed or coastline.Du et al.evaluated six different mooring configurations within the tidal horizontal range, considering static, dynamic, and fatigue analyses.At the same tide level, the variability in fracture strength of synthetic fiber mooring ropes is approximately three times greater than that of chain mooring ropes [54].

The mooring chains are suscept ible to fatigue and corrosion behavior because of the influence of the marine environment[55,56].The corrosion resistance of the mooring chain is crucial for maintaining the stability and precise positioning of the system.Mooring chains are typically manufactured from high-strength alloy steel to withstand heavy loads and resi st corrosion in marine environments.Wang et al.demonstrated that the salt spray corrosion resistance of mooring chains is related to their surface roughness [57].Bergara et al.analyzed the fatigue crack propagation in offshore mooring chains under operational conditions [58].Waves are the main influencing factor of fatigue damage in offshore structures [59].Du et al.evaluated the impact of wave climate and marine corrosio n on the fatigue damage of mooring lines [60].Aursand et al.studied the crack propagation of mooring chains under corrosion conditions.The findings offered a foundation for predicting the fatigue life of mooring lines [61].

The material for anchors is usually high-strength steel to ensure strength and durability in high load and corrosive marine environments.Highe r corrosion levels in the outer ring steel wires increase the system’s overall corrosion [62].Corrosion pits on steel surfaces cause significant stress concentration under axial tension, accelerating the transition from elastic-plastic deformation to brittle fracture.Highe r corrosion levels increase brittleness, making steel wires more susceptible to brittle failure [63].Ji et al.studied the effect of connectors on the motion response of the FPV system, mooring tension and the air gap of the PV panel, demonstrating that a spherical joint aligned with wave propagation effectively reduces mooring tension[64].

The fatigue strength and corrosion resistance of mooring systems are severely affected by the marine environment.Mooring chains are susceptible to wave and salt spray corrosion, leading to increased surface roughness and the generation and propagation of fatigue cracks.The design and material properties of the connectors directly affect the tension distribution and overall stability of the mooring system.High strength steel and optimized spherical joint design have been demonstrated to reduce tension and improve durability.However, there is still insufficient research on the long-term performance of mooring systems under harsh marine conditions, and further exploration is needed for the application of functional materials with corrosion resistance and fatigue resistance.Similarly, it is necessary to improve the fatigue prediction model under the synergistic effect of waves and corrosion to ensure the reliability and stability of mooring systems in harsh marine environments.

3 Methods and suggestions for improving mechanical performance of key components

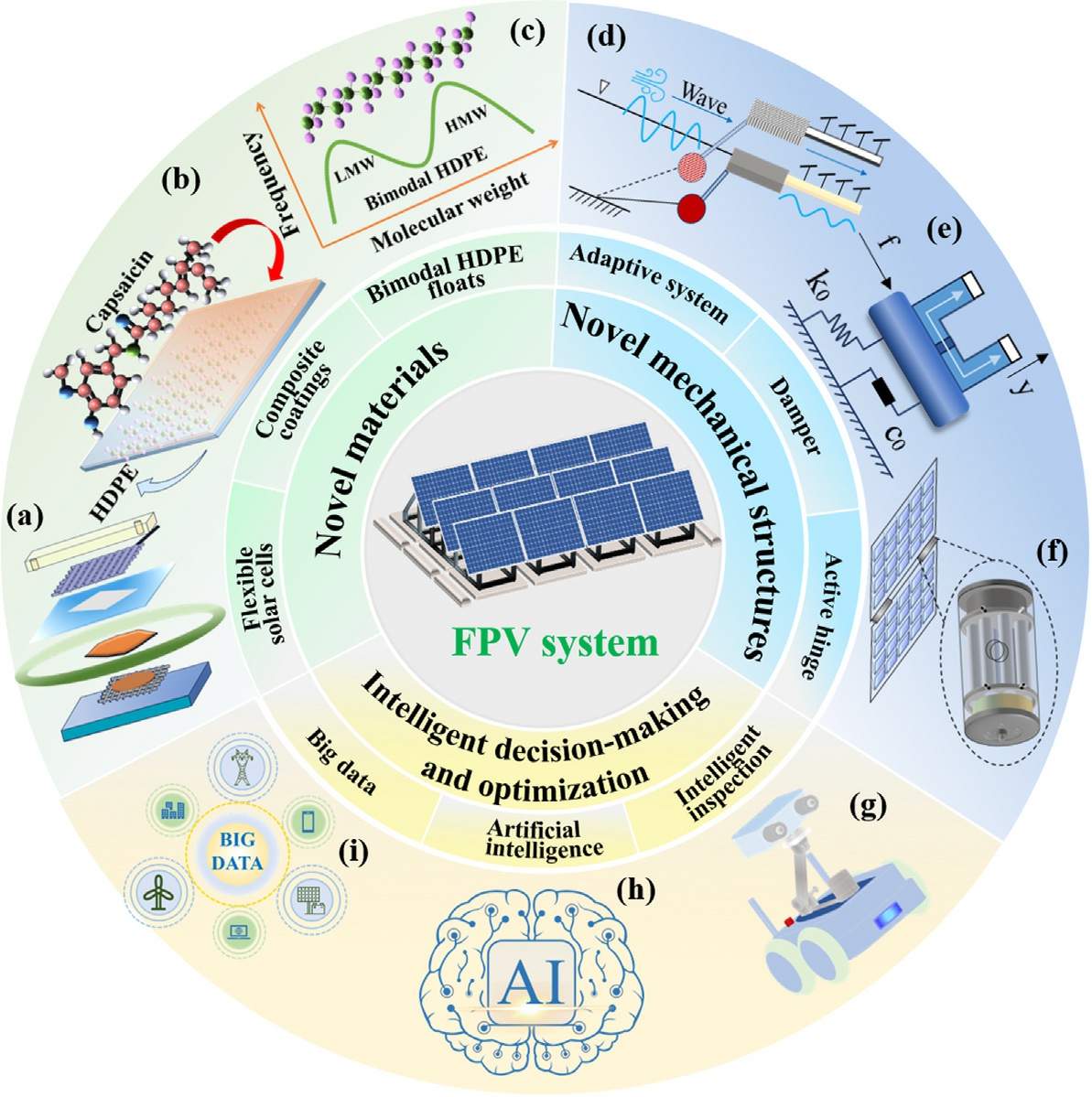

In outdoor environments, polymers are susceptible to degradation due to impurities that are introduced during the manufacturing process.Failures in polymer components are typically attributed to inadequate engineering and material design [65].Therefore, developing novel materials and designing novel mechanical structures can improve the performance of key components in FPV system, ultimately enhancing power generation efficiency.Fig.3 shows the various methods for improving generation efficiency of FPV system.The development of new materials further enhances the stability of offshore PV systems operating in harsh marine environments.The bimodal HDPE material has excellent mechanical properties and can resist the influence of UV radiation.The composite coating on the surface of HDPE further enhances the corrosion resistance of the floating structure.Flexible PV modules have excellent flexibility and buoyancy, which can effectively reduce the weight of the system and the stress borne by mooring.The mechanical stability and energy efficiency of FPV systems are improved by adaptive mooring system, dampers, and active hinges.These novel mechanical structures effectively mitigate the impact of wind and wave forces on the system, reducing damage from vibration and fatigue behavior.Artificial intelligence(AI) techniques like machine learning and deep learning offer significant advantages in predicting key mechanical performance of materials [66].AI techniques enable researchers to understand the constitutive relationship of materials, allowing for improvement s and optimizations to enhance desired mechanical properties [67,68].The application of AI has the potential to significantly enhance the design and optimization of future materials intended for utilization in FPV systems [69].

3.1 Research and development of novel materials

The key components of FPV systems, exposed to harsh marine environments, face unique challenges such as high winds, saltwater corrosion, and extreme weather conditions, all of which can negatively impact performance and durability.To ensure long-term reliability,it is crucial to develop novel materials for key components that offer high mechanical strength and stability.

Lightweight PV modu les can not only reduce the overall weight of offshore support platforms, but also improve the stability of floating platforms and reduce the effect of the marine environment, such as wind and waves, on the platform.By replacing the glass on the front and/or back of PV modules with innovative polymer materials, the weight of the modules can be reduced.Glass-free PV modules made entirely of plastic can be up to 60%lighter than conventional glass-glass modules of the same size [70,71].Therefore,high-quality polymer materials can act as effective moisture barriers, enabling solar cells to withstand high humidity in marine en vironments while maintaining mechanical stability [72].Voronko et al.developed and investigated the novel PET-based frontsheet materials with UV-cured coatings.The results showed that no delamination was observed in the lightweight multilayer composite after 1000 h loading [73].Organic photovoltaic cells(OPVs) have been extensively researched and developed in recent years due to their lightweight and flexible properties, and are expected to be used in offshore PV systems in the future.Li et al.constructed stretchable active layers for OPVs.The optimal PV and mechanical properties of the ternary solar cell were achieved by setting the weight content of PM6-OD in the donor polymers to 20% [74].Choi et al.developed an ultra-flexible OPVs with a new device structure.Despite having undergone 1000 cycles of compressing and releasing at 33% compression, it still maintained high mechanical performance [75].

For floats and structural components, they need to withstand significant loads as well as the effects of saltwater corrosion and biofouling.Sahu et al.concluded that the mechanical performance of bimodal HDPE materials are not significantly affected by accelerated UV irradiation, and proposed that the bimodal HDPE technology significantly improves the mechanical properties of FPV systems [65].

Fig.3.Methods for improving mechanical performance of key components.(a) Flexible solar cells, (b) Composite coatings on the surface of HDPE, (c)Bimodal HDPE materials, (d) Adaptive barrier mooring system, (e) Damper, (f) Active hinge, (g) Intelligent inspection based on robots, (h) Artificial intelligence, and (i) Big data analysis.

Although HDPE is inherently c orrosion-resistant,applying an anti-fouling coating to the float is essential to preserve its mechanical properties [76].The fabrication of structural components frequently involves the utilization of materials such as galvanized steel, with the primary concern for both steel and aluminum being corrosion[77].At present, various composite materials, especially fiberreinforced polymers (FRP), are used in structural components of FPV systems because of their excellent resistance to seawater corrosion and lower density.In fact,FRP has replaced steel or aluminum in the latest FPV designs [78].

FPV systems must withstand mechanical stresses caused by flooding, strong waves, and wind.Therefore, flexible thin-film architectures have been developed to better adapt to the marine environment [79].Bella et a l.[80] proposed the dye-sensitized solar cells (DSCs) based FPV systems.DSCs can be produced using low-density materials, which provide excellent flexibility and buoyancy.Studies have reported power conversion efficiencies exceeding 5% under intense thermomechanical aging tests, with 99% of the initial output retained after undergoing highly rigorous aging conditions.

The development of new materials further enhances the stability of offshore FPV systems operating in harsh marine environments.Lightweight PV modules have been demonstrated to reduce the weight borne by offshore floating structures, thereby enhancing the stability of floating platforms.OPVs have the advantages of light weight and high flexibility, and are expected to be widely used in off-shore FPV systems in the future.The development of composite materials with excellent corrosion resistance and mechanical strength is expected to replace traditional structural components, thereby enhancing the overall reliability of FPV systems.Neverthele ss, the high cost of advanced materials limits their large-scale adoption.In designing flexible materials, further optimization of structural strength is imperative to ensure the adaptability of PV systems to extreme marine environments.

3.2 Design of novel mechanical structures

FPV systems are subjected to continuous environmental stresses, which impact the mechanical stability of the platform, PV modules, and mooring system.To mitigate these effects , it is crucial to modify the mechanical structure to reduce vibration, thereby enhancing system stability and efficiency.Sardar et al.[81] proposed a tuned liquid damper with a floating base, achieving significant reductions of 27.55% in displacement and 32.61% in acceleration under irregular wave conditions.This allows PV mod ules to capture sunlight at optimal angles, thereby boosting power generation efficiency.Similarly, Mohammad et al.[82]developed a shape memory alloy damper, showing that the reductions of over 30% in both displacement and acceleration, leading to better long-term perfor mance.A hinge design proposed by researchers, functioning as an active control method with real-time responsiveness via electromagnetic actuation, has proven effective in reducing lowfrequency vibrations of PV panels [83].The reduction in vibrations helps prevent structural fatigue in the floating platform and PV modules, reducing the risk of damage,and thus improving energy generation over the long term.

Choi et al.analyzed the wind load intensity borne by PV modules and suggested that installing windshields at the edges of PV arrays can reduce wind loads and enhance system safety [84].Chung et al.investigated the impact of side plates on PV panel arrays, demonstrating that such plates significantly reduce wind loads by effectively suppressing the formation and growth of side vortices [85].Cheng et al.demonstrated that floating modular breakwaters are highly effective in reducing wave loads on large floating struc tures.Furthermore,they introduced an innovative lunar pool design for floating bodies[86].Recently,Gayathri et al.studied the utilization of vertical porous barriers as a means of safeguarding floating circular plates from wave forces [87].Bi et al.investigated the efficacy of underwater vertical barriers placed in front of floating platforms to enhance their stability [88].Nonuniform working temperatures and hot spots have been demonstrated to induce power loss as well as permanent thermal strains.Elminshawy et al.developed a novel design heat sink composed of partially submerged angle perforating fins (PSAPF) to solve the heat dissipation problem of off-shore FPV systems.The results demonstrated that,in comparison with conventional FPV systems, the designed system enhanced productivity by 22.77% and diminished operating temperature by 33.31% [89].

The FPV system needs to adapt to water level changes caused by tides and storm surges.Therefore, it is crucia l to improve the fixing devices such as catenary, taut and tension leg [90].At present, elastic mooring lines have been extensively utilized due to their exceptional ductility,enabling them to adapt to fluctuations in water level without compromising their structural integrity[91].Nevertheless, it should be noted that the financial outlay required for the procurement of elastic mooring cables is considerably higher than that associated with the use of steel chains in conventional mooring systems.Zeng et al.proposed a new adaptive barrier mooring system to replace the commonly used elastic cable based mooring system in coastal floating solar power plants.The novel mooring system facilitates the adaptation of floating solar power plants to water depth variations of up to 36%, obviating the necessity for cable slack.Moreover,the nonlinear mooring stiffness and reduced pull-out force on the anchor offer advantages for system design, construction, and maintenance costs compared to elastic mooring systems [92].

Recent studies have demonstrated that the implementation of innovative dampers and active hinge designs can lead to the reduction in vibration and fatigue risks of FPV systems.In addition, side plates, windshields, barriers and floating modular breakwaters have been shown to effectively mitigate the impact of wind and wave forces on the system, thereby enhancing its capacity to adapt to tidal and water level fluctuations.Thus, these novel mechanical structures mitigate the impact of harsh marine environments on entire system.However, the construction and maintenance costs of the new mechanical structures are relatively high.The long-term stability and durability of devices such as dampers, adaptive systems, and active hinges under prolonged exposure to the marine environment have yet to be systematically verified.

3.3 Lifetime evaluation of PV module based on elongation at break

Elongation at break (EAB) is an important indicator for measuring the mechanical properties of insulating materials.We have developed a life evaluation model based on the drop-offrate of EAB to investigate the lifetime of PV backsheets under the influence of temperature and UV irradiation [35].

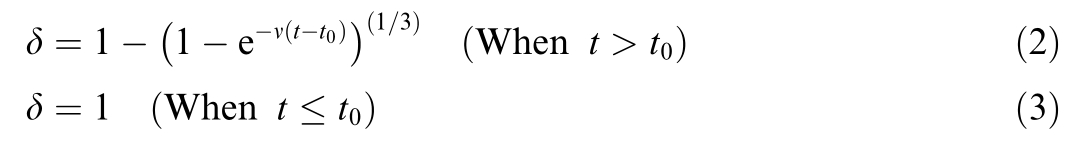

The normalized EAB (δ) after aging can be expressed by Eq.(1).The drop-off rate (v) was measur ed by the deterioration of EAB.

While the decrease of EAB is not significant in the early stage of aging,Eq.(1) should be transformed into Eqs.(2)and (3).

where δ is normalized EAB, ν is drop-off rate whose unit is[1/time], t is aging time, t0 is incubation time.

The results based on the mechanical model indicated that the drop-off rate (v) of normalized EAB of PV backsheets after UV radiation and thermal treatment increa sed from![]() compared with the single thermal effect.The results indicated that, compared to a single stress, the mechanical properties of polymeric backsheets decreased faster under the synergistic influence of multiple environmental stresses.The proposed physical life evaluation model analyzes the mechanical properties of polymeric materials from the drop-off rate of EAB, rather than focusing on internal chemical reactions.The proposed mechanical model based on EAB is expected to provide a reference for studying the changes in mechanical properties of key components in offshore FPV systems under the synergistic effects of various marine environmental factors.

compared with the single thermal effect.The results indicated that, compared to a single stress, the mechanical properties of polymeric backsheets decreased faster under the synergistic influence of multiple environmental stresses.The proposed physical life evaluation model analyzes the mechanical properties of polymeric materials from the drop-off rate of EAB, rather than focusing on internal chemical reactions.The proposed mechanical model based on EAB is expected to provide a reference for studying the changes in mechanical properties of key components in offshore FPV systems under the synergistic effects of various marine environmental factors.

4 Discussion and recommendations for future mechanical properties testing

As an emerging renewable energy technology,FPV systems face more severe environmental challenges than LPV systems, such as high salt spray, strong winds, waves and other factors.These environmental factors have been shown to have a detrimental effect on the mechanical performance of various components of the system, including PV modules, support structures, and mooring systems.Therefore, establishing mechanical performance testing standards for FPV systems can effectively evaluate the durability and resistance of key components in extreme environments, ensuring their long-term stable operation.

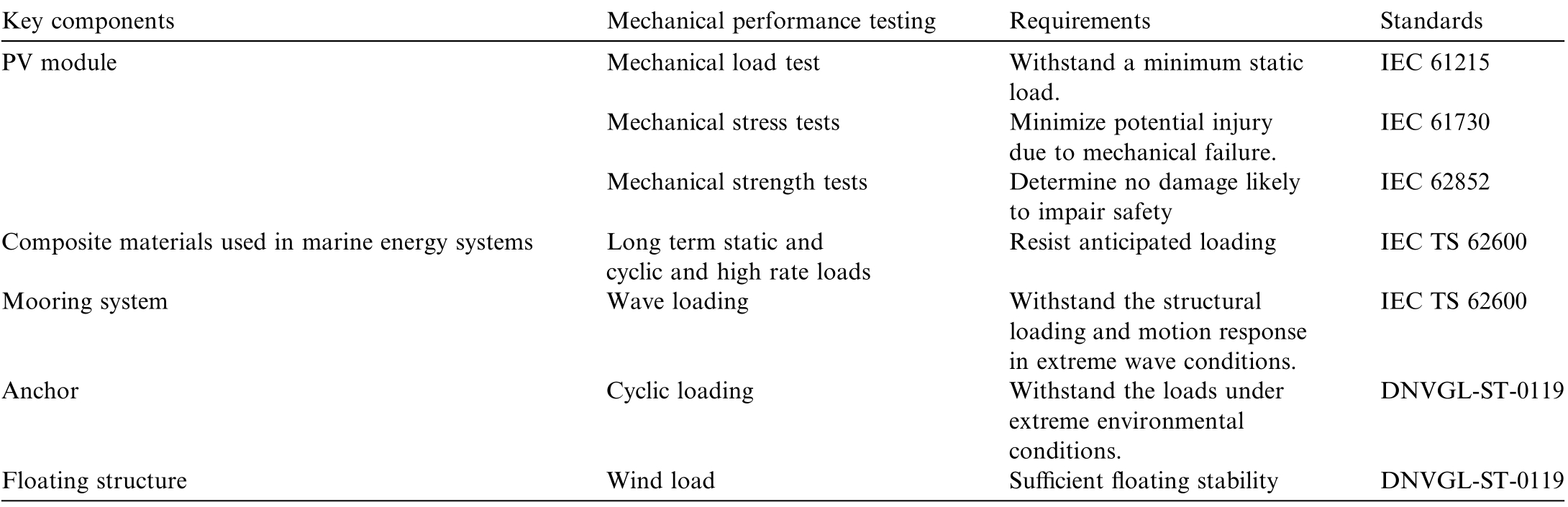

At present, the mechanical performance testing of FPV systems is still in the exploratory stage and has not yet formed a unified international standard.However, some existing standards provide a reference basis for mechanical performance testing of offshore FPV systems.Table 2 shows the requirements for mechanical performance of key components in FPV system.These standards including IEC 61215, IEC 61730 and IEC 62852, mainly cover the safety assessment of PV modules under mechanical loads.Although these standards are primarily designed for LPV modules, they can serve as a reference for FPV modules.However, for FPV systems, the components need to withstand more complex environmental factors, so further optimization of standards is needed to improve applicability.The standards of IEC 62600 and DNVGL-ST-0119 involve the overall design and performance evaluation of the system of offshore renewable energy, covering specific requirements such as mechanical performance and structural stability for key components in FPV systems.In particular, part of the content covers the mechanical performance evaluation of offshore platforms and support structures, providing guidance for the reliability testing of offshore FPV systems.

Although existing standards provide some basic frameworks ,more specific and detailed standards still need to be developed for the mechanical performance testing of various components of FPV systems.Therefore,the establishment of standards for mechanical performance testing of FPV systems needs to focus on the following key areas to ensure long-term stable and safe operation of the system in complex marine environments: (1) Future standards should include more rigorous accelerated corrosion testing to evaluate the corrosion resistance of components in high-tem.salinity environments.(2) The connection between the mooring system and the floating platform is subjected to long-term dynamic loads; therefore, future standards should strengthen testing of tensile, shear,and other mechanical properties of these connection structures.(3)Standards for offshore FPV systems should be developed rapidly, with particular attention to the synergistic effects of mechanical performance degradation across different components on FPV systems.

Table 2 Requirements for mechanical performance of key components in FPV sys

Key componentsMechanical per PV moduleMechanical loa Mechanical str form d tes ess te Mechanical strength c an rate ance testingRequirementsStandards t Withstand a minimum static load.IEC 61215 stsMinimize potential injury due to mechanical failure.IEC 61730 testsDetermine no damage likely to impair safety Composite materials used in marine energy systems Long term stati cyclic and high Mooring systemWave loading IEC 62852 d loads Resist anticipated loadingIEC TS 62600 Withstand the structural loading and motion response in extreme wave conditions.IEC TS 62600 AnchorCyclic loading Withstand the loads under extreme environmental conditions.DNVGL-ST-0119 Floating structureWind load Sufficient floating stabilityDNVGL-ST-0119

5 Conclusion

FPV systems are emerging as an important component for the accelerated decarbonization of global energy generation due to their higher power generation efficiency and lower land requirements.Consequently, the mechanical behavior of key components must be thoroughly studied to ensure the stability and reliability of FPV systems.

The research systematically reviews the mechanical behavior of each structural component in FPV systems under harsh marine environments.It further emphasizes the synergistic effects of mechanical performance degradation among different components on the overall system.The v of normalized EAB of polymer under the synergistic effect of multiple environmental factors increases from 7.5 10 4 h 1 to 21.8 10 4 h 1 compared with the single environmental stress.It also discusses the development of novel materials and innovative mechanical structures applied in FPV systems to enhan ce mechanical performance.The novel flexible PV modules applied in FPV systems minimize the loads acting on the mooring lines by 80% and increase power generation by 5%.Finally, this paper provides a theoretical foundation for developing standards of FPV systems, especially the establishment of standards related to the synergistic effects of the mechanical performance degradation of different components on the overall system.The review is expected to offer theoretical insights and guidance for the material design and structural selection of FPV systems.

6 Future prospects

The future development of FPV systems will benefit from the deep integration of functional mate rials and AI.The development of new PV materials and highperformance smart materials will further improve the effi-ciency and durability of the system, especially in harsh marine environments.AI will optimize the operation of FPV systems through material design, data prediction,and intelligent maintenance, ensuring their efficient power generation under various environmental conditions.FPV systems must withstand extreme environments while maintaining excellent mechanical performance.These challenges are similar to issues such as radiation and temperature difference s in the space environment.Research on the performance and material applications of offshore FPV systems will also providevaluable references for improving the adaptability of PV systems ope rating in extremeenvironm ents such as s pace and the Moon.Space PV systems and lunar surfa ce s olar PV systems will form a new energy nexus, as well as global energy system.In the future,the research will provide fundamental theoretical support for global energy interconnection an d energy e fficiency improvement.

CRediT authorship contribution statement

Kai Feng:Writing - original draft,Methodology,Investigation.Shuaiqi Li: Writing-originaldraft,Investigation.Lin Fu:Resources, Methodology.Yingjiu Zhao:Resources, Investigation.Bin Zhang: Resources, Methodology,Investigation.Sombel Diaham:Resources,Methodology, Investigation.Chatchai Putson: Resources,Methodology, Investigation.Fouad Belhora: Resources,Methodology, Investigation.Abdelowahed Hajjaji:Resources, Methodology, Investigation.Yahia Boughaleb:Resources, Methodology, Investigation.Jiawei Zhang:Writing - review & editing, Resources, Methodology,Investigation, Funding acquisition.

Declaration of competing interest

The au thors declare the following financial interests/personal relationships which may be considered as potential competing interests: ‘‘Lin Fu is currently employed by State Grid Xinjiang Electric Power Co.,Ltd;Yingjiu Zhao is currently employed by China Huadian Engineering Co.,Ltd”.

Acknowledgments

This work is supported by the National Key R&D Program of China (Grant No.2023YFE0114600), The National Natural Science Foundation of China (NSFC)(Grant No.52477029), Joint Laboratory of China-Morocco Green Energy and Advanced Materials, The Youth Innovation Team of Shaanxi Universities and The Xi’an City Science and Technology Project (No.23GXFW0070).The author would like to extend sincere gratitude to all attendees of the 2024 International Conference on Advanced Materi als for Photonics, Sensing and Energy Applications (AMPSECA 2024).

References

-

[1]

A.Djalab, Z.Djalab, A.El Hammoumi, et al., A com prehensive review of floating photovoltaic systems: tech advances, marine environmental influences on offshore PV systems, and e conomic feasibility analysis, Sol.Energy 277 (2024) 112711. [百度学术]

-

[2]

B.Bai, S.Xiong, X.Ma, et al., Assessment of floating solar photovoltaic potential in China,Renew.Energy 220(2024)119572. [百度学术]

-

[3]

A.Ghosh, Potential of building integrated and attached/applied photovoltaic (BIPV/BAPV) for adaptive less energy-hungry building’s skin: a comprehensive review, J.Clean.Prod.276(2020) 123343. [百度学术]

-

[4]

Y.Wang, J.-W.Zhang, K.Qiang, et al., IoT-based green-smart photovoltaic system under extreme climatic conditions for sustainable energy development, Global Energy Interconnect.7(6) (2024) 836-856. [百度学术]

-

[5]

A.Ghosh, A comprehensive review of water based PV:flotavoltaics, under water, offshore & canal top, Ocean Eng.281(2023) 115044. [百度学术]

-

[6]

P.Choudhary, R.K.Srivastava, Sustainability perspectives-a review for solar photovoltaic trends and growth opportunities, J.Clean.Prod.227 (2019) 589-612. [百度学术]

-

[7]

L.Micheli, D.L.Talavera, G.Marco Tina,et al.,Techno-economic potential and perspectives of floating photovoltaics in Europe,Sol.Energy 243 (2022) 203-214. [百度学术]

-

[8]

J.Song, Y.Choi, Analysis of the potential for use of floating photovoltaic systems on mine pit lakes: case study at the Ssangyong open-pit limestone mine in Korea, Energies 9 (2) (2016) 102. [百度学术]

-

[9]

N.A.S.Elminshawy, A.Osama, A.Gagliano, et al., A technical and economic evaluation of floating photovoltaic systems in the context of the water-energy nexus, Energy 303 (2024) 131904. [百度学术]

-

[10]

T.Zarei, M.Abdolzadeh, M.Yaghoubi, Comparing the impact of climate on dust accumulation and power generation of PV modules: a comprehensive review, Energy Sustain.Dev.66 (2022)238-270. [百度学术]

-

[11]

P.Ranjbaran, H.Yousefi, G.Gharehpetian, et al., A review on floating photovoltaic (FPV) power generation units, Renew.Sustain.Energy Rev.110 (2019) 332-347. [百度学术]

-

[12]

T.Hooper, A.Armstrong, B.Vlaswinkel, Environmental impacts and benefits of marine floating solar,Sol.Energy 219(2021)11-14. [百度学术]

-

[13]

R.Claus, M.Lo´pez, Key issues in the design of floating photovoltaic structures for the marine environment, Renew.Sustain.Energy Rev.164 (2022) 112502. [百度学术]

-

[14]

H.Liu, V.Krishna, J.Lun Leung, et al., Field experience and performance analysis of floating PV technologies in the tropics,Prog.Photovolt.Res.Appl.26 (12) (2018) 957-967. [百度学术]

-

[15]

C.K.Liu, Z.R.Kong, M.J.Kao, et al., A novel accelerated aging test for floats in a floating photovolt aic system, Coatings 11 (11)(2021) 1283. [百度学术]

-

[16]

Y.K.Choi, A study on power generation analysis of floating PV system considering environmental impact, Int.J.Softw.Eng.Appl.8 (2014) 75-84. [百度学术]

-

[17]

H.Yousuf, M.Q.Khokhar, M.A.Zahid, et al., A review on floating photovoltaic technology (FPVT), Curr.Photovolt.Res.8(3) (2020) 67-78. [百度学术]

-

[18]

A.Sahu, N.Yadav, K.Sudhakar, Floating photovoltaic power plant: a review, Renew.Sustain.Energy Rev.66 (2016) 815-824. [百度学术]

-

[19]

X.Zhang, W.Wu, H.Fu, et al., The effect of corrosion evolution on the stress corrosion cracking behavior of mooring chain steel,Corros.Sci.J.Environ.Degrad.Mater.Control 203(2022)110316. [百度学术]

-

[20]

N.Kumar, R.K.Pachauri, P.Kuchhal, et al., Floating photovoltaic system based electrical power generation study in Indian context, Renew.Sustain.Energy Rev.212 (2025) 115442. [百度学术]

-

[21]

D.J.Van de Ven, I.Capellan-Pere´z, I.Arto, et al., The potential land requirements and related land use change emissions of solar energy, Sci.Rep.11 (1) (2021) 1-12. [百度学术]

-

[22]

A.Muhammad, U.Muhammad, Z.Abid, Potential of floating photovoltaic technology in Pakistan, Sustainable Energy Technol.Assess.43 (2021) 100976. [百度学术]

-

[23]

A.M.Pringle, R.Handler, J.M.Pearce, Aquavoltaics:synergies for dual use of water area for solar photovoltaic electricity generation and aquaculture, Renew.Sustain.Energy Rev.80 (2017) 572-584. [百度学术]

-

[24]

L.W.Farrar, A.S.Bahaj, P.James, et al., Floating solar PV to reduce water evaporation in water stressed regions and powering water pumping: case study Jordan, Energ.Conver.Manage.260(2022) 115598. [百度学术]

-

[25]

R.Nagananthini, R.Nagavinothini, Investigat ion on floating photovoltaic covering system in rural Indian reservoir to minimize evaporation loss, Int.J.Sustain.Energ.40 (8) (2021) 781-805. [百度学术]

-

[26]

A.Garrod, S.Neda Hussain, A.Ghosh, et al., An assessment of floating photovoltaic systems and energy storage methods: a comprehensive review, Results Eng.21 (2024) 101940. [百度学术]

-

[27]

M.J.Maghrebi, R.M.Nejad, Performance evaluation of floating solar chimney power plant in Iran: estimation of technology progression and cost investigation, IET Renew.Power Gener.11(13) (2017) 1659-1666. [百度学术]

-

[28]

M.Lo´pez, F.Soto, Z.Herna´ndez, Assessme nt of the potential of floating solar photovoltaic panels in bodies of water in mainland Spain, J.Clean.Prod.340 (2022) 130752. [百度学术]

-

[29]

J.Haas, J.Khalighi, A.De La Fuente,et al.,Floating photovoltaic plants: ecological impacts versus hydropowe r operation flexibility,Energ.Conver.Manage.206 (2020) 112414. [百度学术]

-

[30]

M.Kumar, H.M.Niyaz, R.Gupta, Challenges and opportunities towards the development of floating photovoltaic systems, Sol.Energy Mater.Sol.Cells 233 (2021) 111408. [百度学术]

-

[31]

F.Setiawan, T.Dewi, S.Yusi, Sea salt deposition effect on output and efficiency losses of the photovoltaic system; a case study in Palembang, Indonesia, J.Phys.Conf.Ser.1167 (2019) 012028. [百度学术]

-

[32]

O.K.Segbefia, A.G.Imenes, T.O.Saetre, Moisture ingress in photovoltaic modules: a review, Sol.Energy 224 (2021) 889-906. [百度学术]

-

[33]

N.Kyranaki, P.Nivelle, S.Bouguerr a, et al., Investigation of static and dynamic mechanical loads on light-weight PV modules for offshore floating applications, Eng.Struct.319(2024) 118760. [百度学术]

-

[34]

P.Nivelle, J.A.Tsanakas, J.Poortmans, et al., Stress and strain within photovoltaic modules using the finite element method: a critical review, Renew.Sustain.Energy Rev.145 (2021) 111022. [百度学术]

-

[35]

J.W.Zhang, K.Feng, S.Diaham, et al., Lifetime evaluation of photovoltaic polymeric backsheets under ultraviolet radiation:from chemical properties to mechanical modeling, ACS Omega 7(2022) 45609-45616. [百度学术]

-

[36]

P.Perez, S.Iyer, C.Thellen, et al., Thermomechanical and sequential stress performance of photovoltaic backsheets, Sol.Energy 216 (2021) 133-144. [百度学术]

-

[37]

M.D.Kempe, Y.Lyu, J.H.Kim, et al., Fragmentation of photovoltaic backsheets after accelerated weathering exposure,Sol.Energy Mater.Sol.Cells 226 (2021) 111044. [百度学术]

-

[38]

D.Silalahi, A.Blakers, Global atlas of marine floating solar PV potential, Solar 3 (3) (2023) 416-433. [百度学术]

-

[39]

Y.Zhang, C.Yuan, Effects of vibration on output characteristics of shipboard PV modules, Reg.Stud.Mar.Sci.47 (2021) 101989. [百度学术]

-

[40]

S.M.Choi, G.R.Lee, C.D.Park, et al., Wind load on the solar panel array of a floating photovoltaic system under extreme hurricane conditions, Sustain.Energy Technol.Assess.48 (2021)101616. [百度学术]

-

[41]

C.M.Jubayer, H.Hangan, A numerical approach to the investigation of wind loading on an array of ground mounted solar photovoltaic (PV) panels, J.Wind Eng.Ind.Aerodyn.153(2016) 60-70. [百度学术]

-

[42]

V.M.Anh, T.Q.Quan, P.Tran, Nonlinear vibration and geometric optimization of nanocomposite multilayer organic solar cell under wind loading, Thin-Wall.Struct.158 (2021) 107199. [百度学术]

-

[43]

B.Nan, Y.Chi, Y.Jiang, et al., Wind load and wind-induced vibration of photovoltaic supports: a r eview, Sustainability 16 (6)(2024) 2551. [百度学术]

-

[44]

X.H.He, H.Ding, H.Q.Jing, et al., Wind-induced vibrat ion and its suppression of photovoltaic modules supported by susp ension cables, J.Wind Eng.Ind.Aerodyn.206 (2020) 104275. [百度学术]

-

[45]

B.Y.Lim, S.H.Ahn, M.S.Park, et al., Prediction of fault for floating photovoltaics via mechanical stress evaluation of wind speed and wave height, IEEE Access 12 (2024) 70105-70116. [百度学术]

-

[46]

A.Sinha, J.Qian, S.L.Moffitt, et al., UV-induced degradation of high-efficiency silicon PV modules with different cell architectures,Prog.Photovolt.Res.Appl.31 (1) (2023) 36-51. [百度学术]

-

[47]

M.R.Neves, A.Silveira, H.S.Alvarez, et al., Effects of salt spray on c-Si photovoltaic modules in the Brazilian region,in:2023 IEEE 50th Photovoltaic Specialists Conference, San Juan, PR, United states, 11-16 Jun.2023, 2023, p.6. [百度学术]

-

[48]

K.Trapani, D.L.Millar, The thin film flexible floating PV (T3FPV) array: the concept and development of the prototype, Renew.Energy 71 (2014) 43-50. [百度学术]

-

[49]

N.Ravichandran, N.Ravichandran, B.Panneerselvam,Comparative assessment of offshore floating photovoltaic systems using thin film modules for Maldives islands, Sustain.Energy Technol.Assess.53 (2022) 102490. [百度学术]

-

[50]

Y.G.Lee, H.J.Joo, S.J.Yoon, Design and installation of floating type photovoltaic energy generation system using FRP members,Sol.Energy 108 (2014) 13-27. [百度学术]

-

[51]

Y.Zhang, X.Zhang, Y.Chen, et al., A frequency-domain hydroelastic analysis of a membrane-ba sed offshore floating photovoltaic platform in regular waves, J.Fluids Struct.127(2024) 104125. [百度学术]

-

[52]

R.Claus, F.Soto, A.Cebada, et al., Experimental proof-ofconcept of HelioSea: a novel marine floating photovoltaic device,Ocean Eng.299 (2024) 117184. [百度学术]

-

[53]

T.Zou, X.Niu, X.Ji, et al., The projection of climate change impact on the fatigue damage of offshore floating photovoltaic structures, Front.Mar.Sci.10 (2023) 1065517. [百度学术]

-

[54]

J.Du, D.Zhang, Y.Zhang, et al.,Design and comparative analysis of alternative mooring systems for offshore floating photovoltaics arrays in ultra-shallow water with significant tidal range, Ocean Eng.302 (2024) 117649. [百度学术]

-

[55]

R.E.Melchers, T.Moan, Z.Gao, Corrosion of working chains continuously immersed in seawater, J.Mar.Sci.Technol.12 (2)(2007) 102-110. [百度学术]

-

[56]

D.T.Buzzatti, M.Chludzinki, R.E.dos Santos, et al., Toughness properties of a friction hydro pillar processed offshore mooring chain steel, J.Mater.Res.Technol.8 (3) (2019) 2625-2637. [百度学术]

-

[57]

F.Wang, Y.Wang, W.Wang, et al.,Effect of surface roughness on corrosion resistance of mooring chains for offshore floating photovoltaics, Metals 14 (10) (2024) 1181. [百度学术]

-

[58]

A.Bergara, A.Arredondo, J.Altuzarra, et al., Fatigue crack propagation analysis in offshore mooring chains and the influence of manufacturing residual stresses, Ocean Eng.257 (2022) 111605.[59]H.M.Hou, G.H.Dong, T.J.Xu, et al., Fatigue reliability analysis of mooring system for fish cage, Appl.Ocean Res.71(2018)77-89.[60]J.Du, H.Wang, S.Wang, et al., Fatigue damage assessment of mooring lines under the effect of wave climate change and marine corrosion, Ocean Eng.206 (2020) 107303. [百度学术]

-

[61]

M.Aursand, G.T.Frøseth, P.J.Haagensen, et al.,Crack growth in high strength mooring line steel under variable amplitude loading,Mar.Struct.93 (2024) 103534. [百度学术]

-

[62]

W.Shi, C.Yan, Z.Ren, et al., Review on the development of marine floating photovoltaic systems, Ocean Eng.286 (2023)115560. [百度学术]

-

[63]

G.Yao, X.He, H.Long, et al.,Corrosion damage evolution study of the offshore cable-stayed bridge anchorage system based on accelerated corrosion test, J.Mar.Sci.Eng.11 (5) (2023) 896. [百度学术]

-

[64]

C.Ji, X.Gao, S.Xu, Study on the influence of connector designs on the hydrodynamic performance of an offshore floating photovoltaic, Ocean Eng.308 (2024) 118298. [百度学术]

-

[65]

A.K.Sahu, K.Sudhakar, Effect of UV exposure on bimodal HDPE floats for floating solar application, J.Mater.Res.Technol.8 (1) (2019) 147-156. [百度学术]

-

[66]

C.T.Chen, G.X.Gu, Machine learning for composite materials,MRS Commun.9 (2) (2019) 556-566. [百度学术]

-

[67]

F.E.Bock, R.C.Aydin, C.J.Cyron, et al., A review of the application of machine learning and data mining approaches in continuum materials mechanics, Front.Mater.6 (2019) 110. [百度学术]

-

[68]

P.Ball, Using artificial intelligence to accelerate materials development, MRS Bull.44 (5) (2019) 335-344. [百度学术]

-

[69]

J.S.Huang, J.X.Liew, A.S.Ademiloye ,et al.,Artificial intelligence in materials modeling and design, Arch.Comput.Meth.Eng.28(5)(2021) 3399-3413. [百度学术]

-

[70]

M.O.Reese, S.Glynn, M.D.Kempe,et al.,Increasing markets and decreasing package weight for high-specifi c-power photovoltaics,Nat.Energy 3 (11) (2018) 1002-1012. [百度学术]

-

[71]

K.Mik, P.Zawadzki,J.Tarłowski, et al., Multifaceted analyses of four different prototype lightweight photovolta ic modules of novel structure, Energies 14 (8) (2021) 2239. [百度学术]

-

[72]

G.Oreski, J.Stein, G.Eder, et al., Motivation, benefits, and challenges for new photovoltaic material & module developments,Prog.Energy 4 (3) (2022) 032003. [百度学术]

-

[73]

Y.Voronko, G.C.Eder, E.Reiser, et al., Development of novel frontsheets with protective coatings to increase the durability and reliability of glass-free lightweight PV modules, Prog.Photovolt.Res.Appl.(2024) 1-13. [百度学术]

-

[74]

M.Li, K.Xian, W.Zhao, et al., Optimizing mechanical stretchability and photovoltaic performance in all-polymer solar cells from a two-donor polymer blend, Chem.Eng.J.476 (2023)146723. [百度学术]

-

[75]

J.Y.Choi, I.P.Park, S.W.Heo, Ultra-flexible organic photovoltaics with low-temperature deposited IZTO on a cyclic polymer substrate having excellent mechanic al properties, ACS Appl.Mater.Interfaces 13 (43) (2021) 51289-51296. [百度学术]

-

[76]

Y.Liu, X.Shao, J.Huang, et al., Flame sprayed environmentally friendly high density polyethylene (HDPE)-capsaicin composite coatings for marine antifouling applications, Mater.Lett.238(2019) 46-50. [百度学术]

-

[77]

H.Perera, Designing of 3MW floating photovoltaic power system and its benefits over other PV technologies, Int.J.Adv.Sci.Res.Eng.6 (2020) 37-48. [百度学术]

-

[78]

P.Choudhari, V.Kulkarni, S.Khandal, Review on efforts to improve the mechanical performance of fiber-reinforced polymer(FRP) composites under the marine environment, J.Instit.Engineers (India) Ser.C 105 (2024) 241-269. [百度学术]

-

[79]

K.Trapani, S.M.Redo´n, A review of floating photovoltaic installations: 2007-2013, Progr.Photovolt.Res.Appl.23 (4)(2015) 524-532. [百度学术]

-

[80]

F.Bella, A.Lamberti, S.Bianco, et al.,Floating,flexible polymeric dye-sensitized solar-cell architecture: the way of near-future photovoltaics, Adv.Mater.Technol.1 (2) (2016) 1600002. [百度学术]

-

[81]

R.Sardar, S.Chakraborty, Wave induced vibration control of offshore jacket platform by tuned liquid damper with floating base,Ocean Eng.273 (2023) 113948. [百度学术]

-

[82]

M.H.Enferadi, M.R.Ghasemi, N.Shabakhty, Wave-induced vibration control of offshore jacket platforms through SMA dampers, Appl.Ocean Res.90 (2019) 101848. [百度学术]

-

[83]

W.Hu, Q.He, X.Sun, et al., Design of an innovative active hinge for self-deploying/folding and vibration control of solar panels,Sens.Actuators, A 281 (2018) 196-208. [百度学术]

-

[84]

S.M.Choi, C.D.Park, S.H.Cho, et al., Effects of various inlet angle of wind and wave loads on floating photovoltaic system considering stress distributions, J.Clean.Prod.387(2023) 135876. [百度学术]

-

[85]

K.M.Chung, C.Chou, C.Y.Chung, Wind loads on a solar PV panel with side plates, J.Mech.37 (2021) 253-259. [百度学术]

-

[86]

Y.Cheng, C.Xi, S.Dai, et al., Wave energy extraction and hydroelastic response reduction of modular floating breakwa ters as array wave energy converters integrated into a very larg e floating structure, Appl.Energy 306 (2022) 117953. [百度学术]

-

[87]

R.Gayathri, H.Behera, Mitigation of wave force on a circular flexible plate by a surface-piercing flexible porous barrier, Proc.Instit.Mech.Engineers Part M J.Eng.Maritime Environ.235 (2)(2021) 586-599. [百度学术]

-

[88]

C.Bi, M.S.Wu, A.W.K.Law, Surface wave interaction with a vertical viscoelastic barrier, Appl.Ocean Res.120 (2022) 103073. [百度学术]

-

[89]

N.A.S.Elminshawy, A.Elminshawy, A.Osama, An innovative cooling technique for floating photovolt aic module: adoption of partially submerged angle fins, Energy Convers.Manage.X 20(2023) 100408. [百度学术]

-

[90]

R.Cazzaniga, M.Cicu, M.Rosa-Clot, et al.,Floating photovoltaic plants: performance analysis and design solutions,Renew.Sustain.Energy Rev.81 (2018) 1730-1741. [百度学术]

-

[91]

S.Huang, S.Sheng, Y.You, et al.,Numerical study of a novel flex mooring system of the floating wave energy converter in ultrashallow water and experimental validation, Ocean Eng.151(2018)342-354. [百度学术]

-

[92]

F.Zeng, C.Bi, D.Sree, et al.,An adaptive barrier-mooring system for coastal floating solar farms, Appl.Energy 348 (2023) 121618. [百度学术]

Fund Information